DOB-TLS/L series laser rangefinder sensor for laser level gaugeIt is a new generation of non-contact, high-precision distance measuring equipment with powerful functions, The structure is sturdy and designed specifically for industrial and field measurement and monitoring purposes. It is an advanced economic online displacement detection system with astonishing testing accuracy and extremely high stability. Due to its online continuous detection, it eliminates the need for manual point sending like handheld laser rangefinders and can be monitored continuously without human supervision. Its position data can also be transmitted to remote monitoring terminals, making it an ideal instrument for industrial automation and intelligent production management.

Domestic laser displacement sensors can be used inDetect vertical or tilted targets within a range of 30 meters, unaffected by color, material, or glossiness.

180mLaser ranging displacement sensorSensor characteristics

1. Different addresses can be set (up to 249 different addresses can be set), making it convenient for single bus and multi unit networks. And through the specialized connectors produced by our company, sensors can be connected in series without any limit.

2. It has the function of analog reverse output (which can decrease or increase with distance), and the distance corresponding to the analog output range can be adjusted arbitrarily. Very suitable for measuring liquid level, material level, material level, etc. And the analog output is standard 4-20mA, which can be directly connected to PLC, secondary instruments and other equipment for easy network access.

3. It has a switch output function, and the switch output point and switch output status can be adjusted through commands. Suitable for process control, flatness inspection, thickness detection and other occasions.

4. The digital interface forms include RS232, RS422, and RS485, which can be switched freely. Only one communication cable needs to be replaced without making any changes to the sensor.

5. The starting point for distance measurement can be set as the front and rear ends, making it convenient for users to install.

|

model |

DOB-TLS/L series laser rangefinder sensor for laser level gauge |

|

measure distance |

80M |

|

Measurement accuracy(2 σ standard deviation) |

±1.5mm |

|

laser |

650nm / class Class II |

|

measurement frequency |

20Hz |

|

discrete output |

Open circuit output |

|

Analog output |

4-20mA, 0-20mA, 0-5V, 0-10V output |

|

contact method |

standardRS-232 output(Baud rate adjustable 4800、9600、19200、38400) |

|

Pulse triggered measurement, standardRS-232 output (same baud rate as above) |

|

|

standardRS-485 output (same baud rate as above) |

|

|

4-20mA, 0-20mA, 0-5V output |

|

|

Power supply range |

DC : 20-----30 V |

|

maximum power |

P ≤ 1.8W |

|

Operating temperature |

-20ºC to +60ºC |

|

Storage temperature |

-25ºC to +85ºC |

|

Protection level |

IP67 |

App Introduction

1. Remote detection of the position of small objects

Before connecting the inner and outer panels of the car door, it is necessary to encapsulate the essential structural panels, sound insulation panels, and other components of the system in the door and fix them in place. During this process, a small aluminum piece will be welded onto the inner panel of the car door. After the component is placed in place, it will be transported to the robot operation unit where welding will be carried out. If the component is not placed or placed in the wrong position during welding, the door panel will not be usable.

Application: Detecting aluminum parts on car doors

Challenge: Aluminum parts are small and difficult to detect

Solution: KaigitTLS laser ranging sensor

Advantage: The excessive gain is high, so the sensor can detect objects from a certain angle with extremely high accuracy, thus being able to detect subtle changes in the target position.

2. Monitor the height of the material level in the large capacity hopper

The chewing gum has accumulated in the large capacity hopper at the top of the extruder, but it is still being continuously transported into the hopper. Problems with the transportation system and other errors may result in insufficient chewing gum being processed by the system. Errors in the extruder or hopper may cause system blockage or even overflow. Continuously monitoring the chewing gum in the hopper can help identify problems, reduce missed products, and increase productivity.

Application: Monitor the height of chewing gum in the hopper

Challenge: Different colors of chewing gum

Solution: KaigitTLS laser ranging sensor

Advantages: High excess gain and adaptive laser power control, detectableChewing gum of various colors within a range of 30 meters

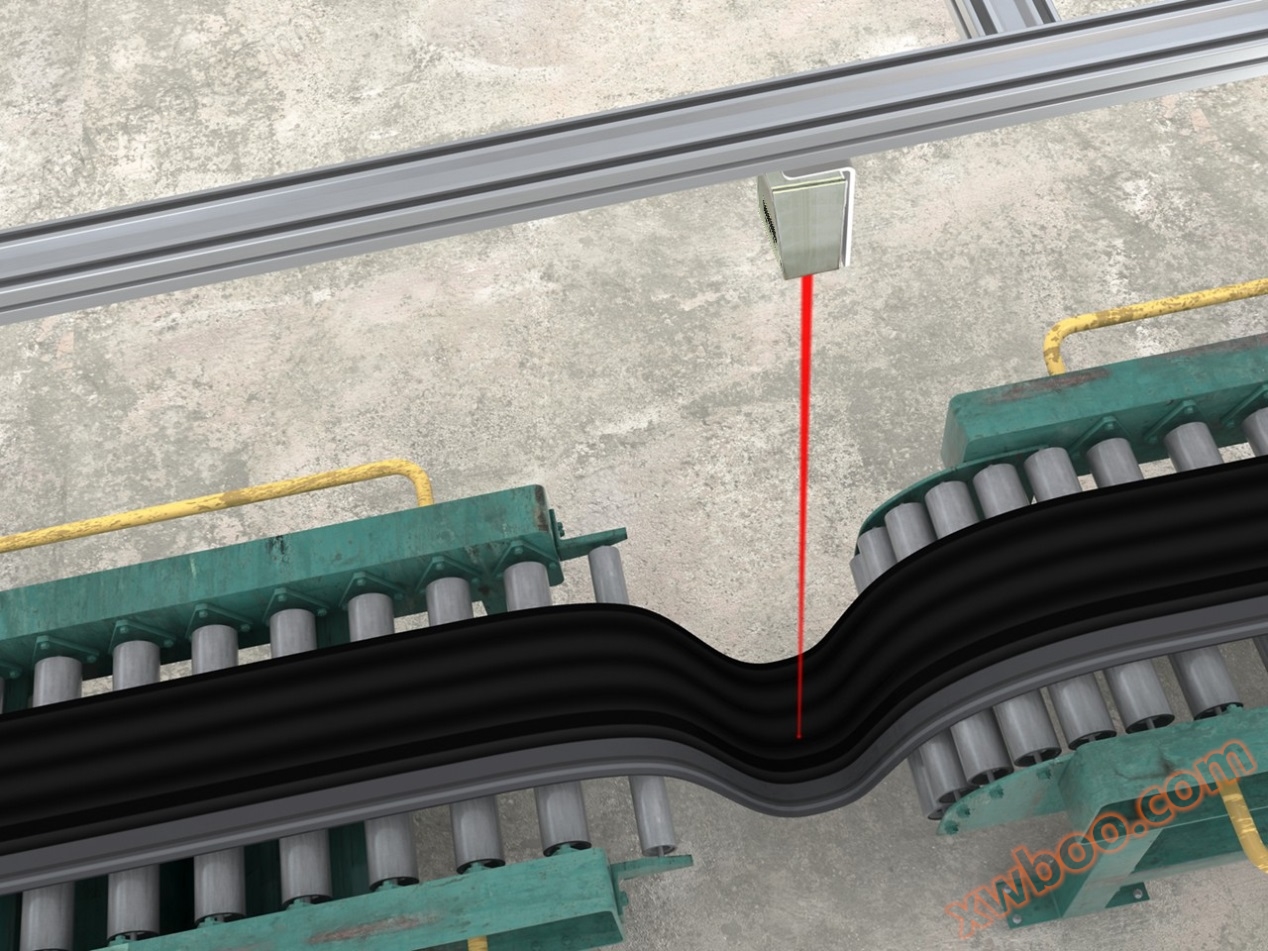

3. Loop control of glowing black tread rubber during tire production process

In the process of manufacturing tires, the tread rubber is processed by a rolling mill and then cut into a certain length. Too tight or too loose tension can cause distortion or damage to the material, making it unusable. The relaxation material loop between processes can adjust this tension. So it is necessary to closely monitor these loops and adjust the machine speed to maintain the appropriate tension of the material. However, for most detection techniques, it is difficult to achieve consistent and accurate detection due to the color and glossiness of this material.

Application: Monitoring the Loop Tension of Tire Rubber

Challenge: The color and glossiness of rubber may vary

Solution: KaigitTLS laser ranging sensor

Advantage: The accuracy of the Kejite laser ranging sensor is not affected by color or reflectivity